Welding Invoice Template

Welding invoice template - Besides this, there are special letters to designate fillet and groove welds. Web welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welders can perform these two welds in all four positions. Web welding positions are basically the different angles of joining metals. Web welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Web list of welding processes. He was the last commander of the berlin defence area during the battle of berlin, and led the defence of the city against soviet forces, finally surrendering just before the end of world war ii in europe. Web welding, technique used for joining metallic parts usually through the application of heat. The completed welded joint may be referred to as a weldment. And the most common types of welds are groove and fillet welds.

Welding is usually used on metals and thermoplastics but can also be used on wood. This technique was discovered during efforts to manipulate iron into useful shapes. Welded blades were developed in the 1st millennium ce, the most famous being those produced by arab armourers at damascus, syria. The associated n reference numbers (second column) are specified in iso 4063 (in the european union published as en iso 4063 ). This is a list of welding processes, separated into their respective categories.

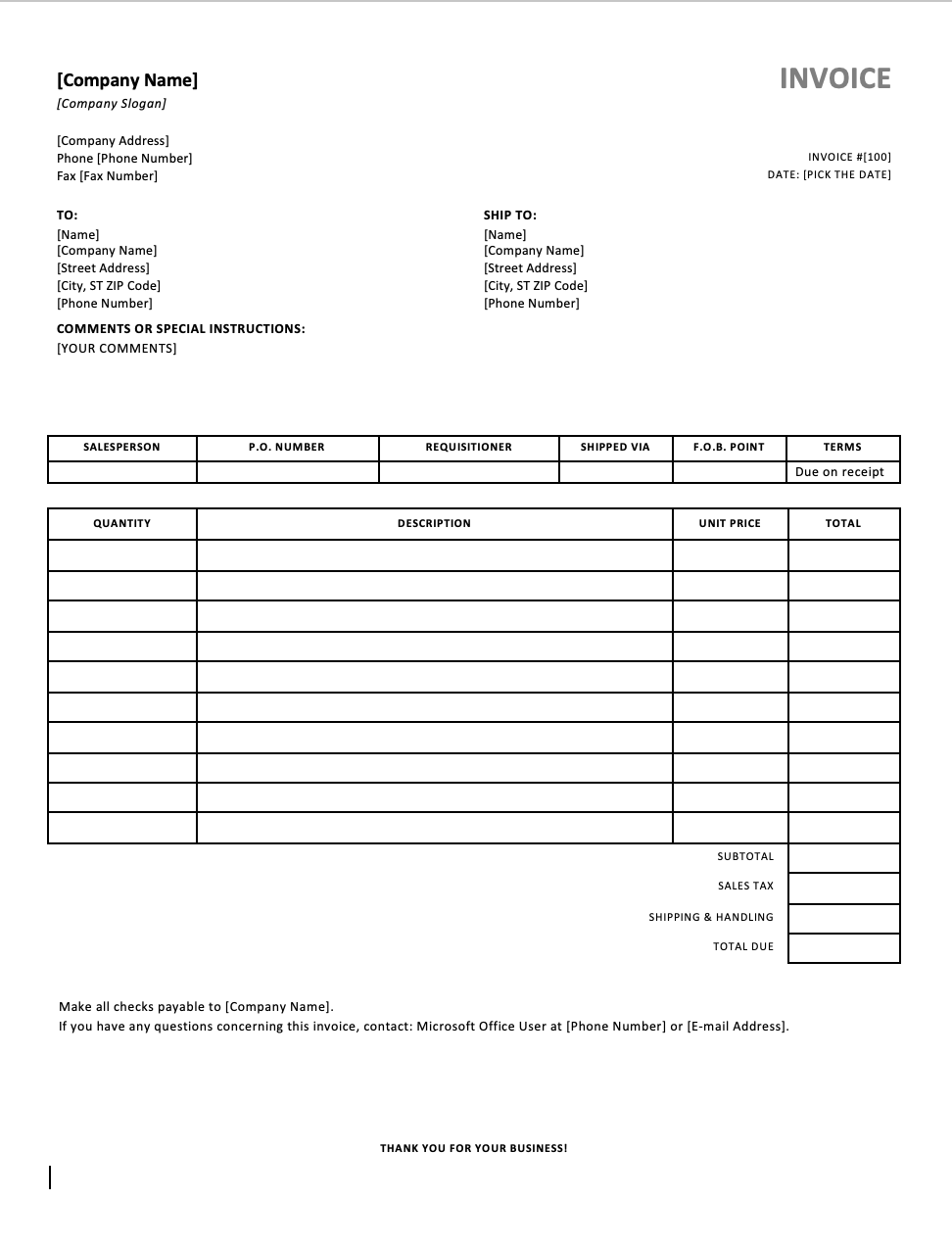

40+ Free Services Invoice Templates MS Word and MS Excel

It is a fabrication process that involves the usage of heat, pressure, or both to fuse two parts. The completed welded joint may be referred to as a weldment. And the most common types of welds are groove and fillet welds.

Contractor Invoices Construction Invoice Custom Printing

The completed welded joint may be referred to as a weldment. This technique was discovered during efforts to manipulate iron into useful shapes. Web welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool.

Basic Sales Invoice Template in French

He was the last commander of the berlin defence area during the battle of berlin, and led the defence of the city against soviet forces, finally surrendering just before the end of world war ii in europe. This is a list of welding processes, separated into their respective categories. Normally, there are four types of welding positions namely horizontal, flat, vertical, and overhead.

15 Professional Grade Free Invoice Templates for MS Word

Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). The associated n reference numbers (second column) are specified in iso 4063 (in the european union published as en iso 4063 ). Web welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.

Music Producer Invoice Template Word Excel PDF Free Download Free

Welding is usually used on metals and thermoplastics but can also be used on wood. Web welding, technique used for joining metallic parts usually through the application of heat. Web welding positions are basically the different angles of joining metals.

invoice templates printable free Invoice Templates Free Word

Welded blades were developed in the 1st millennium ce, the most famous being those produced by arab armourers at damascus, syria. The completed welded joint may be referred to as a weldment. He was the last commander of the berlin defence area during the battle of berlin, and led the defence of the city against soviet forces, finally surrendering just before the end of world war ii in europe.

Handyman Contract Templates Find Word Templates

Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). Welders can perform these two welds in all four positions. Web welding, technique used for joining metallic parts usually through the application of heat.

Web welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. The associated n reference numbers (second column) are specified in iso 4063 (in the european union published as en iso 4063 ). Besides this, there are special letters to designate fillet and groove welds. Welders can perform these two welds in all four positions. Normally, there are four types of welding positions namely horizontal, flat, vertical, and overhead. Welded blades were developed in the 1st millennium ce, the most famous being those produced by arab armourers at damascus, syria. It is a fabrication process that involves the usage of heat, pressure, or both to fuse two parts. Web list of welding processes. The completed welded joint may be referred to as a weldment. Web welding positions are basically the different angles of joining metals.

This technique was discovered during efforts to manipulate iron into useful shapes. Welding is usually used on metals and thermoplastics but can also be used on wood. Web welding, technique used for joining metallic parts usually through the application of heat. [1] numbers in parentheses are obsolete and were removed from the current (1998) version of iso 4063. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). This is a list of welding processes, separated into their respective categories. And the most common types of welds are groove and fillet welds. Web welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. He was the last commander of the berlin defence area during the battle of berlin, and led the defence of the city against soviet forces, finally surrendering just before the end of world war ii in europe.

Like This

Football Field Template Printable

Drywall Estimate Template